Mechanical Design Services

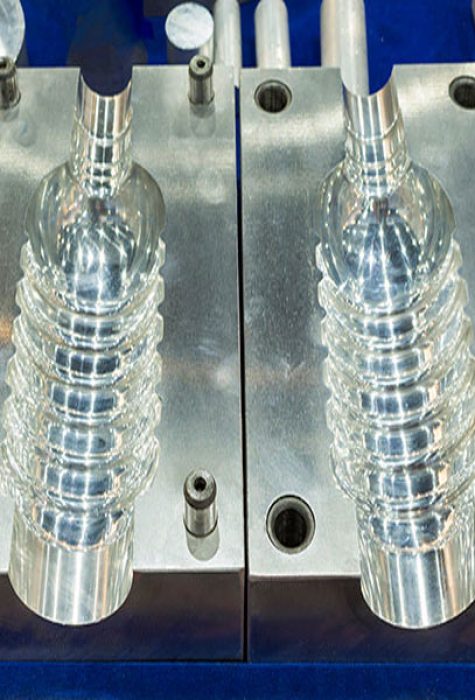

Injection Mold Designing Services

Eunoia Designtech is your qualified supplier for cost efficient, detailed mold designs using 3D CAD software

for your specific requirements. With of product design, molding design and fabrication, and tooling experience,

we have designed and fabricated injection molds, plastic injection molds, wall and ceiling molds, and custom

molds for different companies worldwide. Our mold designs are used in parts that are used in the Automotive,

Electronic Connector, Pharmaceutical/Medical, Aerospace, and General Appliance industries. We design

precision 3D mold designs and tools capable of molding part features to dimensional tolerances of one

thousandth of an inch.

If you have only have concept or design for an injection molded part for your automotive or aerospace

application, we will work with you to design a 3D CAD model of the part. We will test your part in our CAD modeling environment to verify form, fit, and function, as well as compatibility and fit with other parts in your assembly. To ensure your design is moldable, we will design the mold with attention to wall thickness and draft.

We can provide single or multi-cavity, cam action, unscrewing, lifter, stripper plate, 3-plate, or dual ejection molds.

If you have a plastic injection mold project or a mold that needs modifications, Eunoia Designtech is at your

service. Designing injection molded or plastic injected molded parts requires attention to detail. Our expert team

of design engineers will engage with your designers to determine the requirements of your application.

Together, we will determine how the part is to be used, how it mates to other parts within the assembly, what

loads it will experience, and how it will be fabricated. That manner in which the injected medium enters, fills,

and cools within the mold to form the part will be evaluated and taken into consideration during the tooling

process to ensure a successful tool that provides a part that is easy to manufacture and assemble.

Our designers will avoid hard turns and sharp corners to minimize stresses on the formed part, and also avoid

quick transitions from one feature to another that are common locations of stress concentrations due to

molecular bonds relinking as the material cools. In doing so, we will ensure a long-lasting solution by avoiding

stresses that can cause your part to warp, crack, or fail prematurely.

Our design services include solid CAD modeling, tooling feasibility studies, mold design and detail, and plastic

part design. Eunoia Designtech will provide all services and expertise necessary to complete your challenging

tooling project.

Our Expertise in Mold Design Services

At Eunoia Designtech, we provide a variety of Mold Design Services for a variety of industries, from

Automotive to Aerospace to General Appliances. The type of mold depends on your requirements and application. Some of our service offerings include :

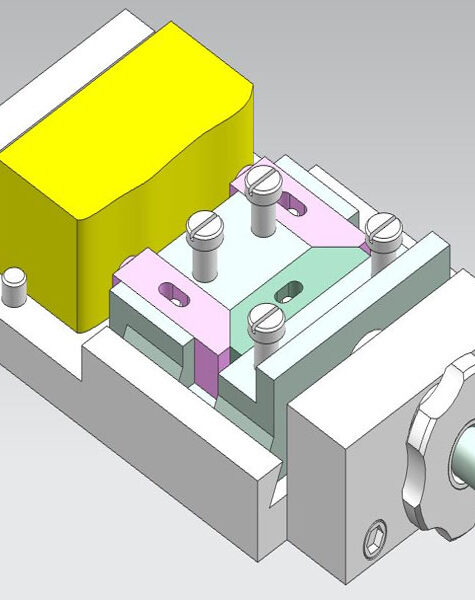

Injection Mold Design :

Our injection mold design capabilities are extensive and comprehensive. We will design molds for your

application, including non-standard tools for co-injection (sandwich), fusible (lost, soluble) core injection,

gas assisted injection, in-mold decoration/lamination, injection-compression, insert, and outsert, lamellar

(micro layer) injection, low-pressure injection, microinjection, powder injection, or push-pull injection

molds.

Plastic Injection Mold Design :

Our Plastic Injection Molds are used to create a multitude of parts from electronic housings to automotive

components. We will guide you through the process of developing molds for high volume of plastic part

fabrication. Our injection molds will allow you to rapidly produce high precision parts with very good

repeatability. Plastic Injection Mold parts are compatible with a large variety of materials. The cost to

produce the parts is very low and the parts need little finishing after molding.

Marketing Material Design :

Our experienced designers work closely with clients to develop custom marketing materials including labels, visiting card, stickers, brochures, flyers, leaflets, catalogs, menus, and more. We pay special attention to the client’s vision while imparting several years’ worth of expertise and knowledge into the design process.

Other Mold Design Expertise

Wall Molding Designs :

Looking for a custom mold solution – look no further. We will find a solution that meets your needs, and

support your design from beginning to end.

Custom Mold and Design :

We will help you turn your artistic ceiling design and patterns into a high yield mold providing parts with

surfaces that require minimal finishing.

Ceiling Molding Design :

Eunoia Designtech is one of the few design houses that specializes in crown molding design. A unique

capability, we can help you customize solutions that set you apart from your competition.

CATIA Mold Design :

Designers are using CATIA more extensively, and the ability to turn your CATIA design into a mold for

Prototype or product fabrication is important to us.

Mechanical Design Services

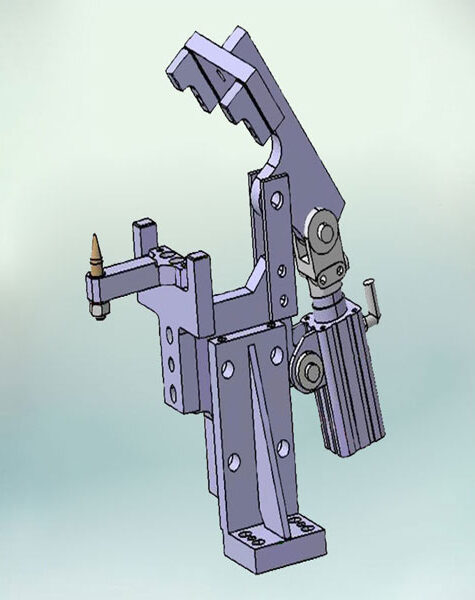

Jigs and Fixtures Design Service

As important as jigs and fixtures are to production processes, it is equally important that they are designed and

manufactured with a supreme degree of accuracy and precision because these tiny tolerances could be the

difference between a faulty final product and a flawless design. Whether you are designing a jig or fixture

design for drilling, turning, grinding or any other machining operations, the effectiveness, accuracy and quality

of your finished product and the retrospective ability to duplicate each and every product with the same

geometrical features depends on the design of the corresponding jigs and fixtures properly

We specialize in providing jigs and fixture design services utilizing the concept of feature based modeling

which lets you access simulation applications that can help you in visually analyzing production processes.

While these also serve as inputs to automated manufacturing applications, our assembly design aids are aimed at

directly relating tooling models and fixture designs to the geometry of the work pieces.

Highlights of our Jigs and Fixtures Design

Highly qualified & experienced team of designers with an advanced level of dexterity with CAD design

application

Ability to cater to your requirements in providing customized and innovative designs for your new product

along with the best customer services.

Our expertise in handling complex designs and new product development cycles.

A blend of least turnaround time and affordable price, resulting in the best savings for you

An efficient design that reduces your production costs and the product lifecycle costs.

Our portfolio of design services encompasses the following

Assembly fixtures

Hydraulic and Pneumatic fixtures

Checking fixtures and check gauges

Testing fixtures

Welding and Machining fixtures

Woodworking jigs and framing jigs

Boring Jig, Drilling Jig

Open or Closed Jig